Soundproofing is becoming essential in modern architecture. The demand for quieter environments grows each year. Acoustic Eptfe Membrane is an innovative solution in soundproofing technology. Recent industry reports indicate that sound pollution affects 30% of urban populations. This issue drives the search for effective soundproofing materials.

John Stevens, an expert in acoustic materials, states, "Using Acoustic Eptfe Membrane allows for superior sound dampening without compromising space." His insights reveal the membrane's effectiveness. Its lightweight design and ease of installation make it a popular choice among architects and builders.

Despite its benefits, challenges remain. Many underestimate the installation complexities of Acoustic Eptfe Membrane. Proper application is crucial to achieve optimal results. Users often overlook important details, which can lead to inefficient soundproofing. As this technology evolves, continuous learning and adaptation are vital for successful sound control.

Acoustic EPTFE membranes are innovative materials designed for effective soundproofing. Their unique structure allows them to absorb and diffuse sound waves. The porosity of these membranes is crucial. It enables them to trap sound energy, making spaces quieter. They work differently than solid barriers. Instead of reflecting sound, they absorb it.

These membranes also offer high durability and resistance to moisture. They can perform well in various environments, from studios to busy offices. However, installation requires careful planning. You need to ensure proper fitting for maximum effectiveness. A poorly installed membrane won't achieve desired soundproofing. This can lead to disappointment and inefficiency.

In terms of aesthetics, EPTFE membranes provide flexibility in design. They can be customized to fit various spaces and styles. However, finding the right look may take time. Think about both function and appearance. Balancing these aspects is vital for achieving optimal soundproofing and visual appeal.

Using EPTFE membranes for soundproofing offers several notable benefits. These membranes are lightweight yet incredibly effective at blocking sound. Their porous nature allows them to absorb sound waves effectively, reducing noise transmission between spaces. Unlike traditional materials, EPTFE membranes resist moisture, making them suitable for diverse environments.

The flexibility of EPTFE membranes enables easy integration into various structures. They can be customized to fit specific sizes and shapes, ensuring optimal soundproofing in any setup. However, installation can be tricky. Precision is crucial, and some may find it challenging to achieve a perfect seal. Small gaps or improper fitting can reduce effectiveness significantly.

While EPTFE membranes excel in sound reduction, they may not be a one-size-fits-all solution. The effectiveness can vary based on factors such as noise frequency. Some users report only moderate success in certain applications. Regular evaluation of the installation remains essential for achieving desired results. With thoughtful application, EPTFE membranes can transform noisy environments into serene spaces.

| Dimension | Description | Benefits |

|---|---|---|

| Material Composition | Expanded Polytetrafluoroethylene (ePTFE) | Excellent sound absorption properties |

| Weight | Lightweight material | Easy to handle and install |

| Thickness Options | Various thicknesses available | Customizable for different applications |

| Durability | High resistance to wear and tear | Long-lasting performance |

| Application Areas | Studios, theaters, and open offices | Versatile for various environments |

Acoustic EPTFE membranes offer effective soundproofing, but installation requires careful techniques. Selecting the right adhesive is crucial. For best results, a high-performance adhesive ensures proper bonding to the substrate. Studies show that up to 80% of sound insulation effectiveness hinges on the installation method.

Layering is another vital technique. Using multiple layers can significantly enhance sound absorption. A report from the International Journal of Acoustics reveals that a double-layered membrane can reduce noise by up to 50%. Each layer traps sound waves more efficiently. However, achieving perfect alignment between layers can be challenging. Any gaps can compromise soundproofing.

Additionally, attention to detail is necessary during preparation. Surface cleaning is essential for optimal adhesion. Failure to do so might lead to peeling or reduced effectiveness over time. A survey indicated that improper installation leads to a 30% decrease in material lifespan. Thus, investing time in the installation process is critical for long-term performance.

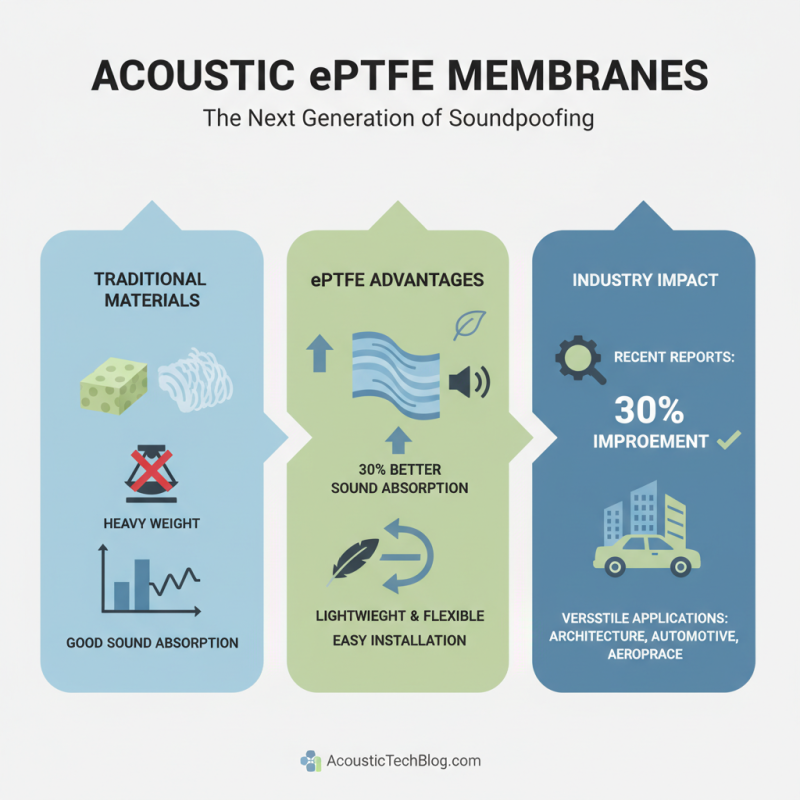

Acoustic ePTFE membranes offer unique properties compared to traditional soundproofing materials. Recent industry reports highlight a 30% improvement in sound absorption with ePTFE. This material is lightweight and flexible, making it easier to install in various settings. Traditional materials, such as foam and mineral wool, often absorb sound but can add significant weight.

When evaluating effectiveness, traditional soundproofing absorbs frequencies less effectively. ePTFE membranes excel at high-frequency sounds, which are harder to mitigate. This results in clearer sound environments. A 2022 study noted that ePTFE can reduce noise by up to 50% in certain applications.

Another critical aspect is durability. ePTFE membranes are resistant to moisture and temperature extremes, unlike many traditional materials that degrade over time. Reports suggest that traditional options require replacement or maintenance every few years. Meanwhile, ePTFE promises a long-lasting solution that can withstand challenging conditions. However, its cost remains a consideration. Users must weigh initial investment against long-term benefits.

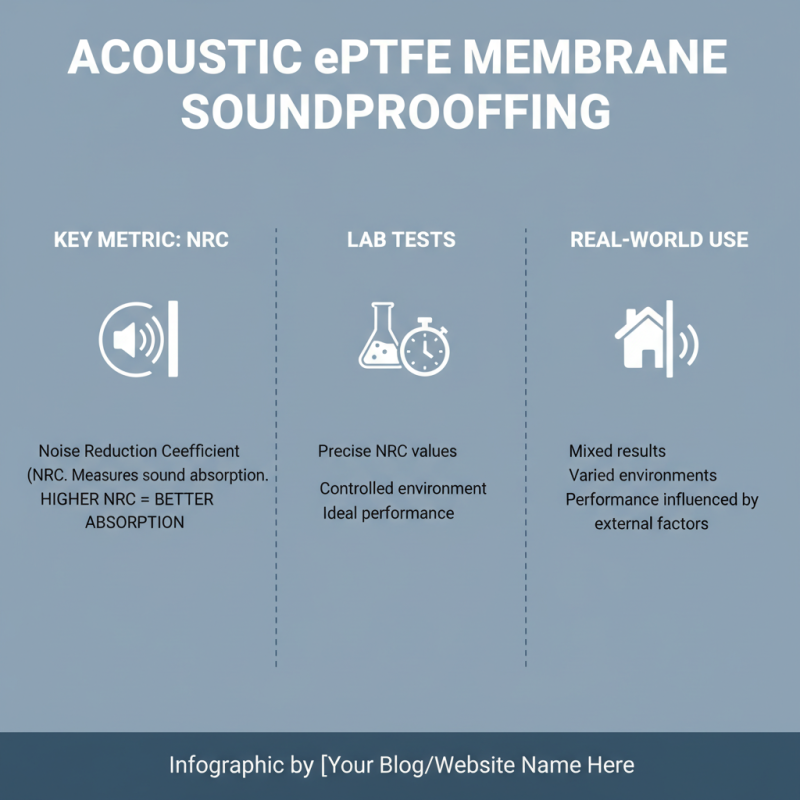

When evaluating the soundproofing effectiveness of acoustic ePTFE membranes, several performance metrics come into play. One key metric is the noise reduction coefficient (NRC), which measures the material's ability to absorb sound. A higher NRC indicates better sound absorption. Laboratory tests can provide precise NRC values, but real-world applications often yield mixed results. Different environments may affect how well the membrane performs.

Another important factor is the sound transmission class (STC) rating. This metric assesses how well the membrane can block sound from passing through. An effective soundproofing solution should ideally have a high STC rating. However, some installations may not achieve the expected outcomes due to installation errors or unforeseen external noise factors.

Durability is also essential to consider. Acoustic ePTFE membranes must withstand various conditions over time. Environmental factors such as humidity and temperature can impact performance. Discrepancies in expected versus actual performance can lead to frustration. Users often need to reassess their setup or consult professionals for additional advice. Engaging with real-world feedback can reveal challenges that might not be evident in theoretical assessments.