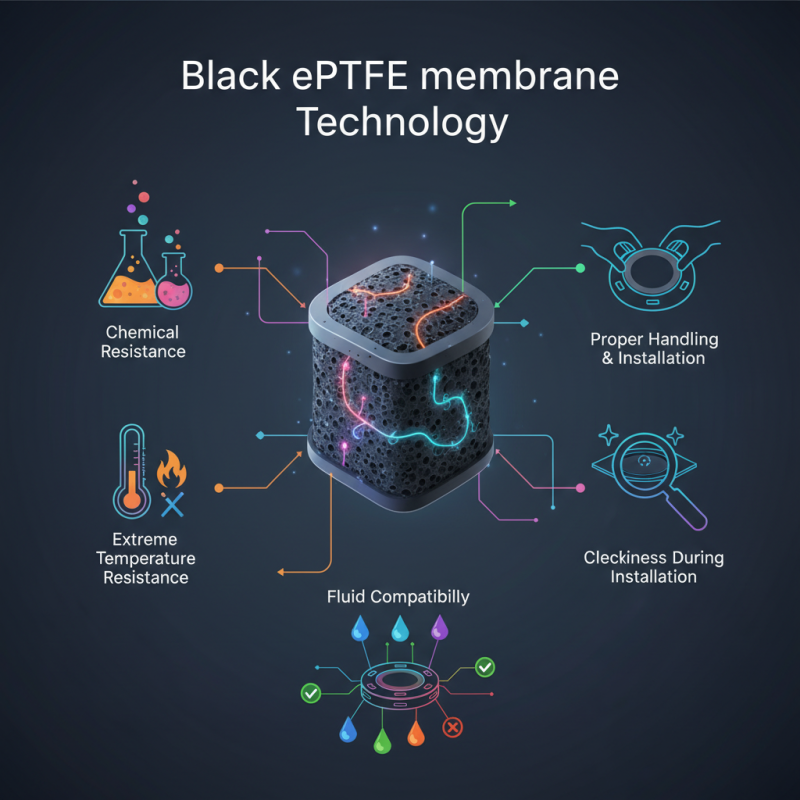

In the ever-evolving field of filtration technology, the "Black Eptfe Membrane" stands out for its unique properties and performance. Dr. Sarah Lin, a leading expert in membrane technology, once stated, "The Black Eptfe Membrane transforms the way we think about filtration efficiency." This highlights its significance and the need for optimal use.

Black Eptfe Membrane is not just a material; it is a solution for diverse applications. Its exceptional resistance to chemicals and extreme temperatures makes it a preferred choice in various industries. However, proper handling and installation techniques are often overlooked. Users frequently underestimate the impact of installation errors on overall performance.

Attention to detail is crucial. Users should ensure cleanliness during installation. Contaminants can hinder efficiency, yet this aspect is often neglected. Additionally, the compatibility of the Black Eptfe Membrane with specific fluids must be considered. Without careful application, even the best materials may underperform. Recognizing these factors can lead to significant improvements in efficacy and longevity.

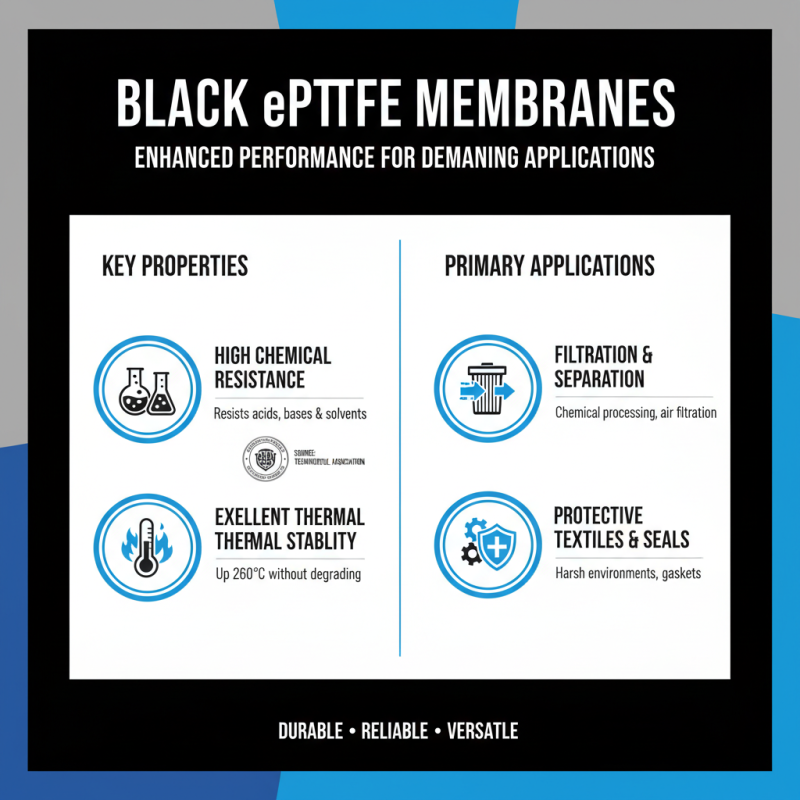

Black Expanded Polytetrafluoroethylene (ePTFE) membranes possess unique properties that enhance their performance in various applications. These membranes are notable for their high chemical resistance and excellent thermal stability, making them suitable for harsh environments. A report from the Technical Textile Association states that ePTFE membranes can withstand temperatures up to 260°C without degrading, which is critical for many industrial processes.

The unique porous structure of black ePTFE membranes allows for superior filtration efficiency. They feature a fine microporous structure that enables the separation of particles as small as 0.2 microns. This property is particularly beneficial in industries such as pharmaceuticals and food processing, where contamination must be minimized. However, there are challenges. Users often report issues with membrane clogging, which can lead to decreased efficiency over time. Regular maintenance and monitoring are essential to address this problem.

Additionally, the hydrophobic nature of black ePTFE membranes makes them ideal for water and oil separation tasks. They repel water while allowing vapor to pass through. Nevertheless, this hydrophobic characteristic can also cause issues under specific conditions, such as high humidity. Users should be aware of these limitations and adjust their applications accordingly.

Black EPTFE membranes are gaining traction across various industries. Their unique properties make them ideal for diverse applications. For instance, in the pharmaceutical sector, these membranes act as effective barriers. They maintain sterility and prevent contamination. However, choosing the right membrane for each process is crucial.

In the automotive industry, black EPTFE membranes are useful in filtration systems. They ensure clean air intake, improving efficiency. Yet, some manufacturers struggle with installation errors. Improper fitting can lead to decreased performance. It's important to understand the specifications and configurations needed for optimal results.

Additionally, these membranes are used in environmental applications. They serve in gas and liquid separation. However, some challenges remain. Understanding the chemical compatibility is vital. Overlooking this can lead to failure in harsh environments. The industry's awareness regarding these limitations needs improvement. The benefits of black EPTFE membranes are clear, but careful consideration is key.

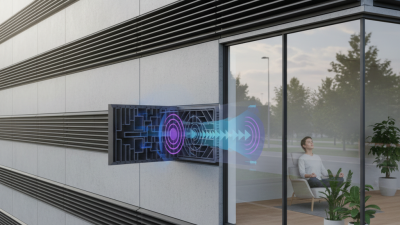

Black EPTFE membranes are known for their excellent durability and chemical resistance. To ensure optimal performance, installation and maintenance practices should be prioritized. According to industry reports, improper installation can lead to significant material inefficiencies, reducing membrane life by up to 30%.

Before installation, check all surfaces thoroughly. Any contaminants can affect adhesion. Ensure that the area is dry and clean. A consistent temperature during installation is essential. Ideal conditions are between 15°C and 25°C. Temperature fluctuations can impact performance.

For ongoing maintenance, inspect the membranes regularly. Look for signs of wear or damage. Even small tears can compromise functionality. Cleaning is also critical. Use a mild detergent and water. Harsh chemicals can degrade the EPTFE.

Tip: Regular checks every six months are advisable to catch issues early. Relying solely on initial quality is a misstep. Reflect on past experiences; each project is unique. Overlooking simple maintenance can lead to costly repairs later on. Always act proactively.

| Aspect | Details |

|---|---|

| Material | Expanded Polytetrafluoroethylene (ePTFE) |

| Temperature Resistance | -200°C to 260°C (-328°F to 500°F) |

| Typical Applications | Filtration, medical devices, automotive components |

| Installation Tips | Ensure surface cleanliness, use appropriate adhesives |

| Maintenance Recommendations | Regular inspections, avoid abrasion and chemical exposure |

| Lifespan | Up to 10 years under ideal conditions |

| Compatibility | Compatible with most chemicals except strong oxidizers |

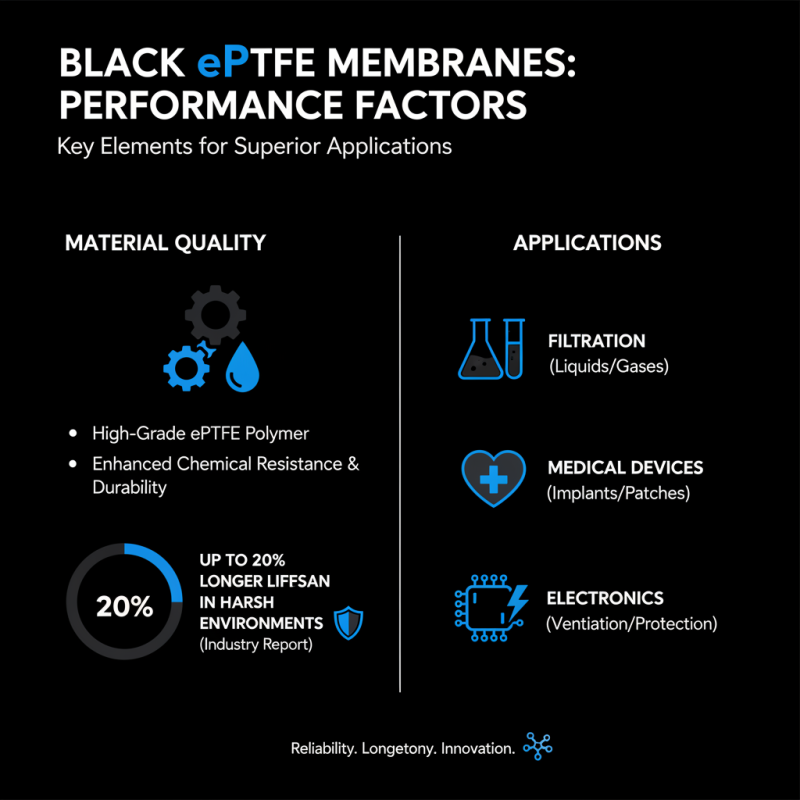

Black ePTFE membranes are increasingly popular for various applications, from filtration to medical devices. Understanding the factors that influence their performance is essential. Material quality is a major factor. High-quality ePTFE provides better resistance to chemicals and enhances durability. According to recent industry reports, membranes crafted from premium materials can last up to 20% longer in harsh environments.

Porosity is another critical element. The pore size affects fluid movement and overall filtration efficiency. Membranes with optimized pore structure are found to improve performance significantly. Studies indicate that a well-tuned porosity can enhance airflow by over 25%. This adjustment can lead to increased productivity in industrial applications.

**Tips for Optimal Use:** Always consider the operational environment when selecting a membrane. Ensure compatibility with the intended medium. Regularly inspect the membranes for signs of wear. This practice can prevent unexpected failures. Adjust maintenance schedules based on usage patterns. Ignoring this can lead to reduced membrane life and performance issues.

Black EPTFE membranes are known for their excellent chemical resistance and stability. However, users often encounter common issues that can adversely affect their performance. One prevalent problem is membrane fouling. Studies indicate that 30% of failures in filtration systems stem from inadequate cleaning protocols. This fouling can result in reduced flow rates and compromised efficiency, impacting production.

Another frequent issue is the improper replacement of membrane elements. This can lead to leakages and inconsistent performance. Experts suggest regular inspections should be implemented. In fact, nearly 25% of companies neglect these essential maintenance checks. This oversight not only increases operational costs but can also lead to unplanned downtime.

Understanding these challenges is vital. Users need a proactive approach to ensure optimal membrane performance. Without regular maintenance and proper troubleshooting, black EPTFE membranes may underperform. Feedback loops and documentation are crucial for improvement. By addressing these issues, facilities can enhance their membrane longevity and reliability, thereby optimizing production outcomes.